I. Project overview

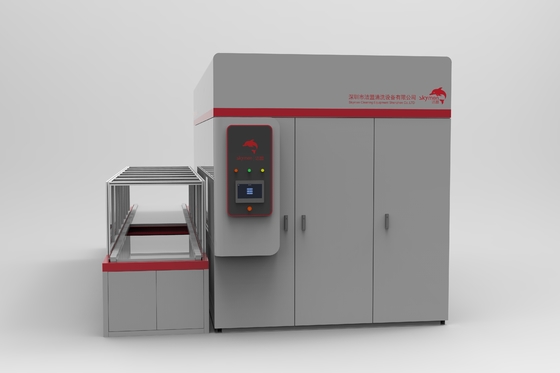

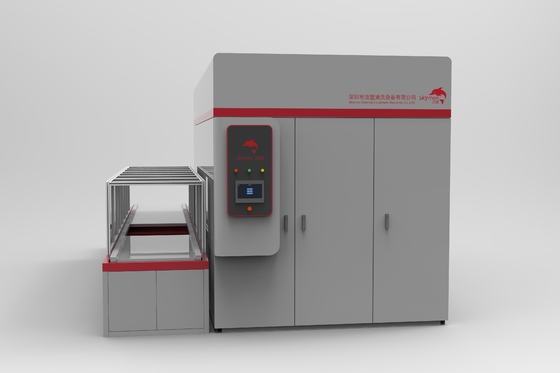

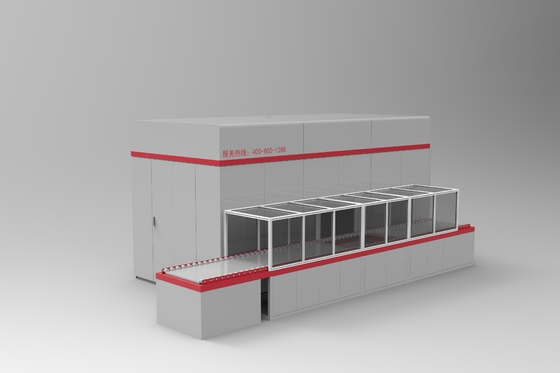

1,Project name: 4 stages automatic ultrasonic cleaning machine

2,Project requirements:Based on the product information and cleaning technical requirements provided by customers, on the basis of meeting the technical agreement and production requirements, we will provide customers with mature, reliable, stable and excellent performance of automatic cleaning equipment to meet the use requirements, and provide customers with complete after-sales service and use technical guidance.In this project, Party B (the Seller) shall be responsible for the equipment design, manufacturing, commissioning, quality and after-sales service, and the project construction shall be completed according to the agreement reached with the customer before the sale.

II. Equipment details

1,Equipment overview:

1.1 The fully automatic cleaning machine model JTM-4096SD is a high-intelligence and high-precision cleaning equipment designed and manufactured for customer products; it mainly uses ultrasonic cleaning, to clean, rinse and dry customer products; So that the cleanliness of the customer's workpiece can meet the requirements of use, The equipment has 4 cleaning chamber, loading and unloading table. The equipment is completed automatically, without the need for personnel to be on duty, and manual intervention can also be carried out as needed.

1.2 The model is JTM-4096SD automatic cleaning machine mainly by:

1 ultrasonic occurrence system (including generators, transducers),

2 holding system (cleaning tank),

3 heating system,

4 liquid level control system,

5 Induction positioning system

6 PLC control system,

7 Robot arm system.

8 Basket dunking/agitator system for all the cleaning chamber

Among them,

1 The physical shock generated by the ultrasonic occurrence system is the most important way of cleaning;

3 The heating system is to sensing the heating temperature by high precision temperature probe to realize the start-stop control of the heating device;

4 The level control system is a real-time induction of the amount of cleaning solution in the tank to realize the amount control of cleaning solution;

5 Induction positioning system helps mechanical grip precision positioning to improve grasp accuracy and effectiveness;

6 PLC control system is the start and stop and cleaning process, And according to the actual situation of the cleaning process for preparation or manual intervention;

7 The robot arm system is an effective way to carry and smoothly transport products into the next cleaning process

- The dunking system allows the workpiece to fully rub with the cleaning solution and quickly wash away the cleaning solution in the previous process and at the same time strip off the tiny attachments

2,Basic parameters of equipment

| 2.1 Cleaning parts information |

Customer provide |

| 2.2 Chamber size |

Tank size: 750(L)*500(W)*550(H) mm

Basket size: 650(L)*400(W)*450(H) mm

Material: SUS304

|

| 2.4 Required wire size |

25 Square Aluminum wire or 16 square copper wire |

| 2.5 Power of the cleaning machine |

≈42kW |

| 2.6 Robot arm quantity |

1pc |

| 2.7 Washing beat |

15~30min |

| 2.8 Machine dimension |

About 5800x2400x2600mm,The actual size prevail |

| 2.9 Power demand for equipment |

380V±10%/50Hz,3 phase |

| 2.11 Remote control |

Software problem that cause performance problem should be done by remote on device by Skymen engineer |

3,Working process:

3.1 To be washed products:???

3.2 Cleaning process:

Loading

→ 1 ultrasonic cleaning for 15 minutes (Solvent: Soap detergent)

→ 2 Ultrasonic rinsing for 5 minutes (Solvent: DI Water)

→3 Hot water rinsing for 5 minutes(Solvent: DI Water)

→4 Hot water rinsing for 5 minutes (Solvent: DI Water )

Unloading

3.3 Cleaning agent type:Organic solvents, DI water

3.4 Description of the cleaning process configuration:

| No. |

cleaning liquid |

Cleaning method |

ultrasonic |

auxiliary facilities |

heating power |

| 1 |

Soap detergent |

ultrasonic cleaning |

40kHz/2.4kW |

Basket Agitator/dunking |

6kW |

| 2 |

DI Water |

ultrasonic rinsing |

40kHz/2.4kW |

Basket Agitator/dunking |

6kW |

| 3 |

DI Water |

Hot water rinsing |

/ |

Basket Agitator/dunking |

6kW |

| 4 |

DI Water |

Hot water rinsing |

/ |

Basket Agitator/dunking |

6kW |

- Allocation description of cleaning system

4.1 Ultrasonic cleaning

| No. |

1st tank |

| Structure |

Tank size |

750x500x550mm |

| Basket |

650x400x450mm |

| Tank material |

AISI304,thickness 2mm |

| Ultrasonic system |

Transducer |

48pcs ultrasonic transducer, the total ultrasonic power is 2.4kW, and the power is continuously adjustable |

| Generator |

Imported IGBT sweep control board with uniform ultrasonic output, output power with photoelectric display and current display |

| heating system |

temperature control |

Digital display, temperature control range RT-90℃ |

| heating power |

Place a 6kW stainless steel heating pipe inside the tank |

4.2 Ultrasonic rinsing

| No. |

2nd tank |

| Structure |

Tank size |

750x500x550mm |

| Basket |

650x400x450mm |

| Tank material |

AISI304,thickness 2mm |

| Ultrasonic system |

Transducer |

48pcs ultrasonic transducer, the total ultrasonic power is 2.4kW, and the power is continuously adjustable |

| Generator |

Imported IGBT sweep control board with uniform ultrasonic output, output power with photoelectric display and current display |

| heating system |

temperature control |

Digital display, temperature control range RT-90℃ |

| heating power |

Place a 6kW stainless steel heating pipe inside the tank |

4.3 Hot water rinsing

| No. |

3rd tank |

| Structure |

Tank size |

750x500x550mm |

| Basket |

650x400x450mm |

| Tank material |

AISI304,thickness 2mm |

| heating system |

temperature control |

Digital display, temperature control range RT-90℃ |

| heating power |

Place a 6kW stainless steel heating pipe inside the tank |

4.4 Hot water rinsing

| No. |

4thtank |

| Structure |

Tank size |

750x500x550mm |

| Basket |

650x400x450mm |

| Tank material |

AISI304,thickness 2mm |

| heating system |

temperature control |

Digital display, temperature control range RT-90℃ |

| heating power |

Place a 6kW stainless steel heating pipe inside the tank |

5,Main mechanical structure

5.1 Robot arm

| Quantity |

1 set |

| structure |

The structure of the robot arm is a single-arm beam type, which is stable in operation, accurate in positioning, large in bearing capacity, strong in flexibility and fast in lifting. |

| electrical control |

▶The robotic arm is controlled by a programmable controller and proximity and induction switches to automatically complete the cleaning process; the cleaning rhythm is adjustable, and the operation process is variable frequency speed regulation, which can achieve soft landing and accurate positioning

▶Established with a washing basket protection device, when there is a basket in the tank, the robotic arm shall not place any more baskets

|

| Motor parameters |

Lifting |

Geared motor, power: 3/4HP, speed: 0-7 m/min (parameters are designed on demand) |

| Moving |

Servo motor, power: 1HP, speed: 0-7 m/min (parameters are designed on demand) |

|

Can achieve

Function

|

▶ Manual operation;

▶ Fully automatic operation;

▶ Automatic reset system;

▶ Pause and emergency stop;

▶The man-machine interface modifies the program;

▶The man-machine interface adjusts the process parameters;

▶Can remotely monitor and control equipment operation;

▶HMI fault alarm display.

|

| load bearing |

Max. 50kg |

5.2 Machine frame chassis and door panel

| quantity |

1 set |

| structure |

The frame and chassis of the entire equipment are made of stainless steel

The front and rear and left and right sides of the equipment are equipped with decorative door panels, which are mainly composed of brushed stainless steel and acrylic panels. The surface is matte and beautiful.

The water distribution tank is set on the rack, and the foot cup is set at the bottom

|

5.3 Air release

| quantity |

1set |

| material |

Stainless steel, PVC engineering plastics |

| installation site |

A suction cover can be set up above the organic solvent and water-soluble solvent cleaning tank, which can be connected to the customer exhaust system, and the air valve can be adjustable |

5.4 Basket

| quantity |

6pcs |

| material |

AISI 304 |

5.5 Electric control system

| quantity |

1 set |

| material |

Stainless steel board |

| structure |

▶The electric control cabinet is located on the left side of the first tank and is assembled with the cleaning system; install the touch screen of the operation panel and display the working status of the whole machine simultaneously;

▶The buzzer and the equipment shall have three-color working indicator lamp, abnormal situation prompt sound and light alarm;

▶PLC, relay, air switch, transformer and other main order control circuit is configured in the cabinet;

▶The line layout is neat and clear, with a clear line number.

|

III. Spare part List

| Spare parts |

Brand |

| Transducer |

Skymen |

| Generator |

Skymen |

| Cylinder |

Air TAC |

| Geared Motor |

Delta |

| Servo Motor |

Delta |

| Cooling fan |

AIRMATE |

| Heater |

JIUKOU |

| PLC |

Delta |

| Touch screen |

WEINVIEW |

| Digital temperature controller |

Omron |

| Solenoid value |

Air TAC |

| Level switch |

Skymen |

| Photoelectric switch |

Omron |

| Capacitive approach switch |

Omron |

| Manual water inlet/outlet Value |

Skymen |

| Y-Value |

Skymen |

| Power switch |

Delta |

| Relay |

Schneider |

| Linear Guide Rail |

PMI |

| Frame/Shell |

Jinshuncheng |

| Tank |

Jinshuncheng |

IV. Documents and spare parts shipped with machine

1,Relevant technical documents

| Name |

language |

quantity |

Remarks |

| Manual |

English |

1 |

|

| circuit diagram |

English |

1 |

|

| piping diagram |

English |

1 |

|

| Water/electric installation diagram |

English |

1 |

|

| Daily Maintenance Instructions |

English |

1 |

|

2,Spare parts

| Name |

Quantity |

| heating pipe |

4pcs |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!